Agricultural components are subject to some of the harshest conditions out there, so they must be designed for maximum strength and durability. Lutco recently worked with the engineering team of a global Fortune-500 agricultural manufacturer to redesign an adjustable slotted assembly used in corn harvesting equipment. The two teams applied collaborative engineering strategies to develop an improved part solution that increased performance and reduced manufacturing costs.

Part Failure Analysis Leads to Innovation, Cost Reduction

Lutco’s engineers were brought on to help solve premature component failure in the auger end plates of their newest corn head. The corn head is a critical piece of commercial agricultural equipment, harvesting crops and grinding down the remaining stalk left above the ground after harvest.

The failure points were flangettes securing the bearings to the auger end plates, which were not able to withstand the operation of the machine in the field. After a thorough review of the design, Lutco’s engineering team made recommendations on ways to improve the strength of the flangette.

Using the information gained through the collaborative engineering review, the customer’s engineers brought a new design for an adjustable slotted assembly to Lutco for feedback. This new solution incorporated customized flangettes, allowing a threaded rod to be inserted through a hole above the bearing flangettes to adjust the height of the shafting.

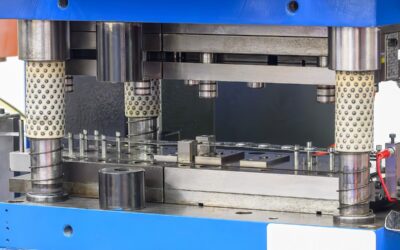

The new design concept was a big improvement, but Lutco’s engineers realized that the new flangette would require unique tooling, which would incur additional costs and delay the production cycle. The Lutco engineers reviewed the parts Lutco was already manufacturing for this customer’s other products and recommended a suitable flangette design that could be adapted, allowing them to apply the same tooling for two different assemblies. The combination of new and existing part designs would be a solution that not only improved the performance of the product but also reduced manufacturing costs.

Redesigning Agricultural Components for Strength and Durability

Originally the flangettes had an offset form and were heat treated to help them survive the challenging environment. The new part was thicker and composed of a stronger material, HSLASF-50. A more symmetrical shape was reinforced with gussets to strengthen the flange, helping it to resist the force of the turning auger. Heat treating was no longer necessary thanks to the stronger material, eliminating an additional manufacturing step from the process. The parts were also coated with zinc plating to prevent rusting and corrosion.

The collaboration between Lutco and the customer’s engineers showcased how effective concurrent engineering can be when it comes to product development. The new part enabled the customer to create an effective piece of equipment that would bring the most value to users. This project also showed how Lutco engineering strives to provide a solution in any type of manufacturing situation, no matter how complex or challenging it may be. As a result, the product’s end users are now enjoying the benefits of this new part with its lower-cost solution and superior performance.

Collaborative Engineering Brings New Insight to Legacy Products

This example proves the power of collaboration and demonstrates how important concurrent engineering is for modern-day manufacturing. By leveraging the expertise of both parties, solutions can be created faster and more efficiently than ever before. The result is an improved product that maximizes value to customers. Through this type of collaboration, companies can continue to keep up with the ever-evolving needs and trends in the manufacturing industry.

If you’re looking for a reliable partner to help solve your manufacturing challenges, look no further than Lutco. With their extensive engineering and product development expertise, they have the knowledge and resources to tackle challenges head-on. Their collaborative approach to concurrent engineering offers more cost-effective solutions that maximize customer value by delivering superior performance.