Precision Machining

Lutco is fully committed to producing perfection in machining, time to market, and customer satisfaction.

We offer an array of machining capabilities for producing complex, tight-tolerance components with faster throughput, reduced cost and exceptional quality. Our capabilities include multi-spindle screw machines, multi-axis CNC lathes, multi-axis CNC Swiss machines, vertical CNC machining centers and routers. With such a variety of choices available to our manufacturing engineers, your products can be produced in the best possible manner, saving precious time and reducing critical costs.

Typical materials processed in our machining centers include, but are not limited to, carbon steel grades 12L14, 1215, 41L40, C1018, 52100, stainless steel grades 303SS, 306SS, aluminum grades 2011T3, 7075, 6061T6 and 360CDA grade brass, as well as Delrin and Teflon plastic.

Lutco utilizes Mastercam, Partmaker and Esprit CAM software for CNC machine programming. From these software tools, CAM information is seamlessly exported directly to the work centers allowing for quick setups and minimal programming time.

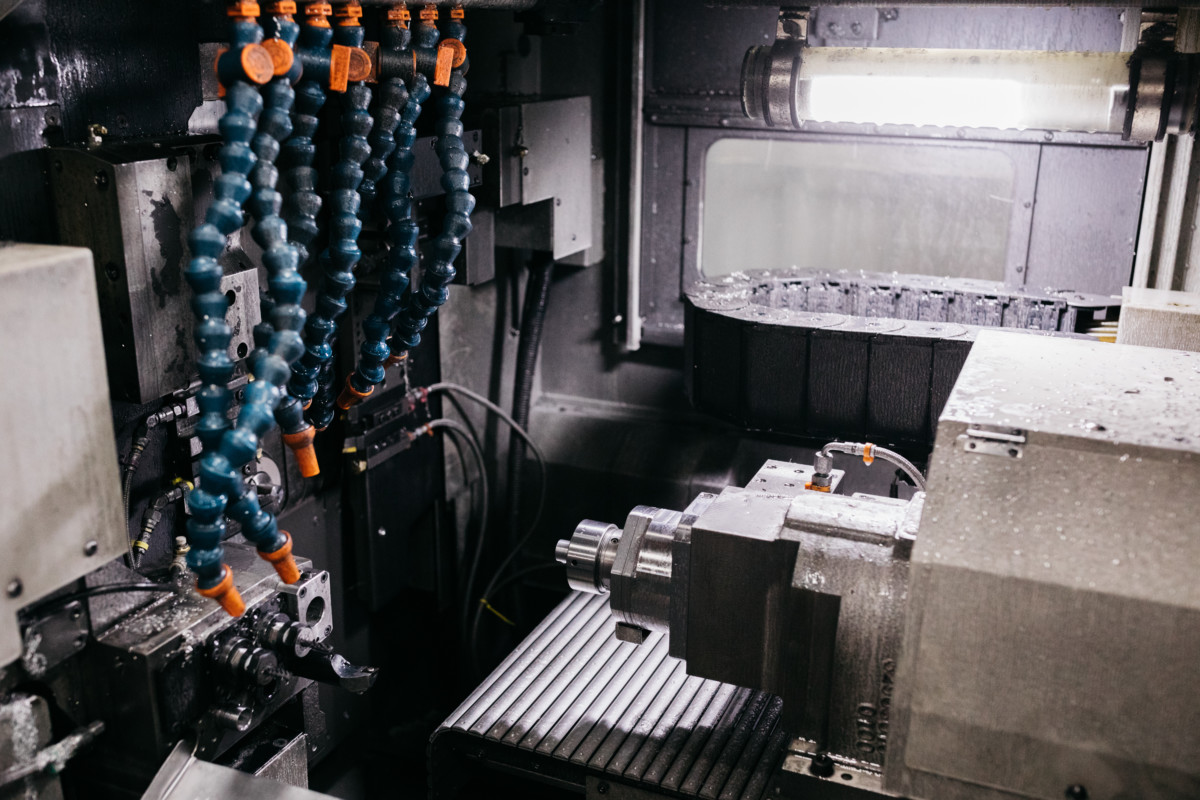

CNC Turning Machines

Our multi-axis CNC turning centers allow us to produce complex precision components in low-to-high volumes (250 pieces minimum). Our machines leverage live tooling for off-axis machining operations, as well as integrated bar feeding systems for speed and bar stock diameters up to 3.5″. In addition, our CNC chucker lathe can machine up to 15″ diameter blanks. The minimum volume for machining blanks is 50 pieces.

- OD Capacities: Up to 3.5″ round bar-stock for bar fed machines

- Length capacities up to 24”, dependent on part geometry

- 15″ Diameter chucking capacity

- Machining Capabilities: Tapping, threading, drilling, cross drilling, grooving, knurling, milling, counter sinking, and broaching.

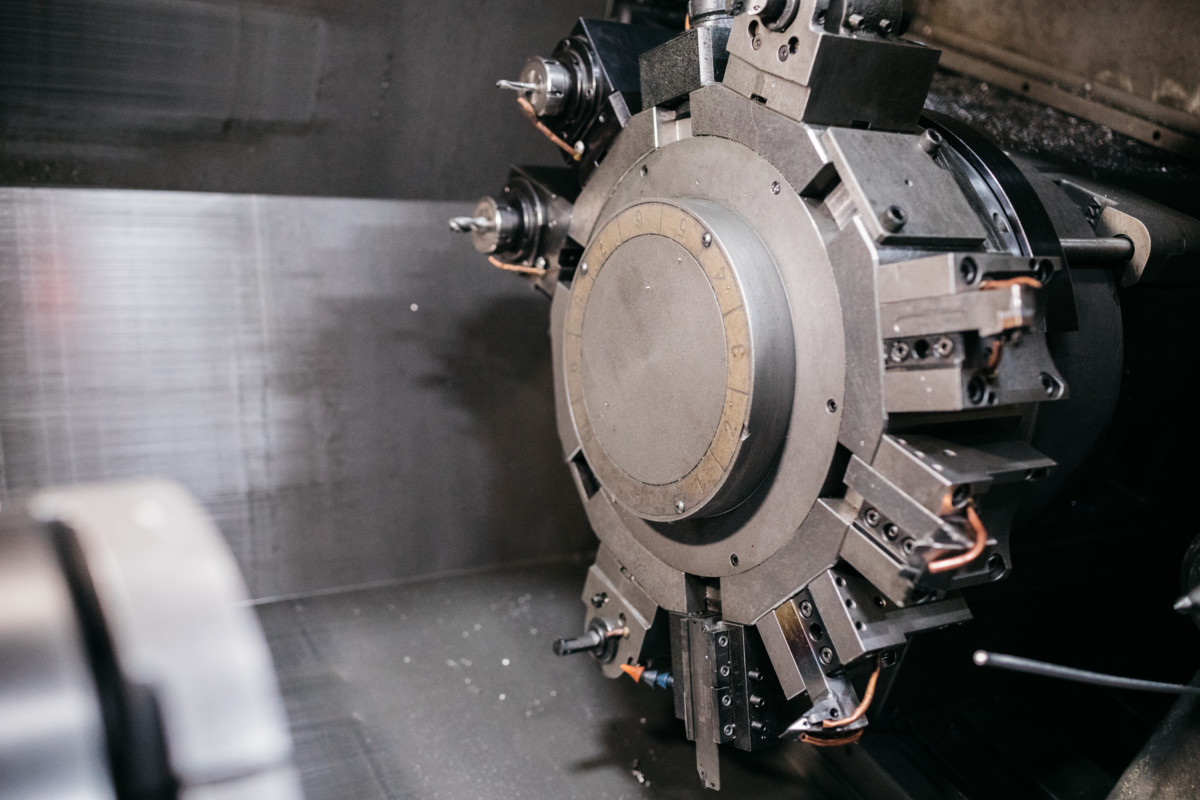

CNC Swiss Machines

When you need CNC Swiss screw machined components, turn to a partner with a proven record of consistent quality and on-time delivery. Our bar fed Tsugami 8-axis and 11-axis CNC Swiss automatic lathes machine our most intricate parts. Swiss machines are ideal for creating small, precision parts with finer finishes and tolerances to .0001 in, and are suitable for low-to-high volume jobs (250 pieces minimum). Single point turning can be utilized to economically produce complex parts in a single setup, avoiding costly tool purchases and lead times. Use of multiple axes (x,y and z) as well as simultaneous main and sub-spindles allow us to manufacture to your most complex part specifications.

- OD Capacities: 1.50″ (38MM) round bar-stock, 30″ max length

- Machining Capabilities: Cross drilling, drilling, cross tapping, threading, slotting, knurling, counter sinking, milling, broaching

Acme Gridley and Davenport Multi-Spindle Screw Machines

Our Acme Gridley 6-spindle and 8-spindle screw machines economically manufacture precise parts from ferrous and red metals, in large production volumes of 5,000 pieces or more.

- OD Capacities: Up to 2-5/8” round bar-stock, 6” max length

- Machining Capabilities: Turning, drilling, knurling

- Machining Capabilities: Drilling, reaming, tapping, threading, knurling, counter sinking, recess machining, and back-working

Davenports are versatile, 5-spindle screw machines that cost-effectively produce complex small-to-medium size parts with tight tolerances. Ideal for plumbing, electrical, automotive, controls, and hardware applications, Davenports are best utilized for minimum production volumes of 20,000 pieces.

- OD Capacities: Up to 7/8″ round bar-stock, 3/4″ hex bar-stock

- Length Capacity: 2.5″ max length

- Machining Capabilities: Cross drilling, drilling, reaming, cross tapping, threading, slotting, knurling, counter sinking, milling, and back-working

Contact us to find out why leading OEMs rely on Lutco!