The economic impact of the ongoing COVID-19 pandemic isn’t just staggering— it’s literally historic. At one point during April, the United States Treasury Secretary estimated that unemployment rates could reach as high as 20% in the United States before all of this is over. Somewhere between 50-60% of all employees are either working remotely or, in many cases, aren’t working at all.

As companies understandably seek to reinvigorate the United States’ economy following these unprecedented levels of business disruptions, many have chosen to reshore component procurement and assembly operations to reduce the risk of repeating the mistakes of the past that could lead to a catastrophe in the future. Placing an emphasis on stamped metal components made in the USA at this particular moment in history is a decision that brings with it a wide array of different benefits, all of which are more than worth exploring.

The Critical Role of Reshoring Metal Stampings and Components in a Post-COVID World

In general, the advantage that reshoring stamped metal components brings with it ultimately comes down to far shorter supply lines, fewer complications or risks, and reduced overall cost. Not only will it be easier to maintain total visibility over the entirety of the supply chain, but it will also mean that products move through those supply lines (and into the hands of customers) at a far faster rate as well.

But maybe the most immediate benefit that reshoring offers comes down to the fact that it’s simply far easier to do business in the United States than it is in other countries. In addition to a lower overall cost— dramatically so, in some situations— you also need to consider the fact that the federal government appears ready to levy billions of dollars in new tariffs on foreign imports sooner rather than later.

Tomorrow’s Success Depends On Strong Manufacturing Partnerships Today

Considering how the challenges that come with a long and complex supply chain are now evolving, it shouldn’t come as a surprise that many reputable OEMs and high-quality distributors are turning to partners like Lutco to produce parts that they formerly brought into the country from places like China, thanks to the assurance of more reliable products, superior delivery, and lower overall long-term cost.

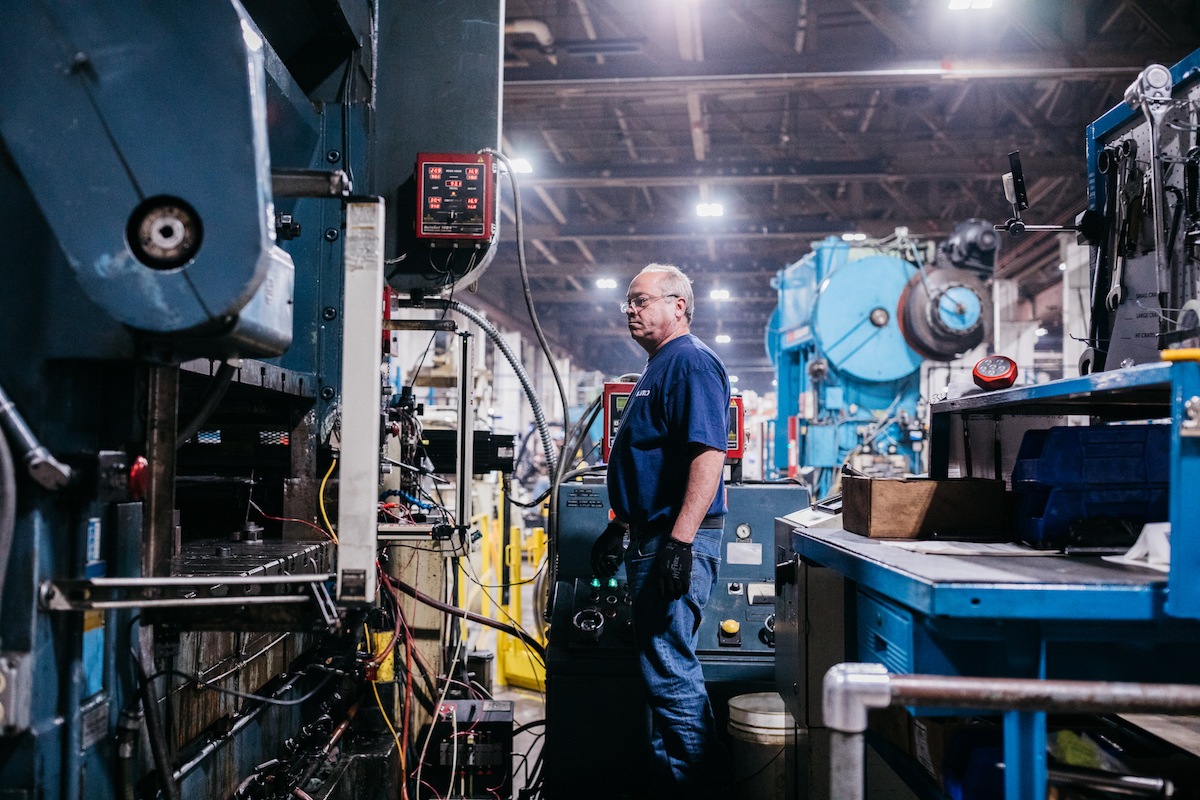

When you work with Lutco, we don’t just sell you a new part. We do whatever it takes to help OEMs identify the causes of problems so that they can be solved permanently. Our customers reap the benefits of smarter manufacturing, while also keeping costs low and supporting stamped metal components made in the USA.

Lutco has been manufacturing bearings, flangettes, pillow blocks, and other stamped metal components in the United States for over 75 years and our skilled operators have decades of combined experience between them. We’ve worked hard to develop our reputation as a “one stop shop” with a wealth of capabilities and services, all located under one convenient roof.

While it’s fair to say that the COVID-19 pandemic has been an enormous challenge for all of us, it’s also an opportunity waiting to be taken advantage of by savvy businesses, as well as a potential boon to US job creation. Lutco has a long history of supplying the most reputable names in agriculture, outdoor power equipment, and material handling with parts that go into products that rely on a reputation of quality and reliability. We’re committed to upholding our customers’ reputations for reliable, robust products, and will do our part to help them succeed via reshoring and beyond.