At Lutco we strive to foster long-lasting relationships that transcend generations. In fact, 25% of our full-time workforce has 20-40 years of steady employment at our company. We take great pride in knowing that we offer the rare kind of stability and security that can provide careers for multiple generations within a family.

One remarkable example can be found in the story of the LeBoeuf family, where 3 generations of expert machinists and toolmakers found success through a career at Lutco. We spoke with Rick to learn about the impact the company had on his family and his life, as well as his advice for future Lutco employees.

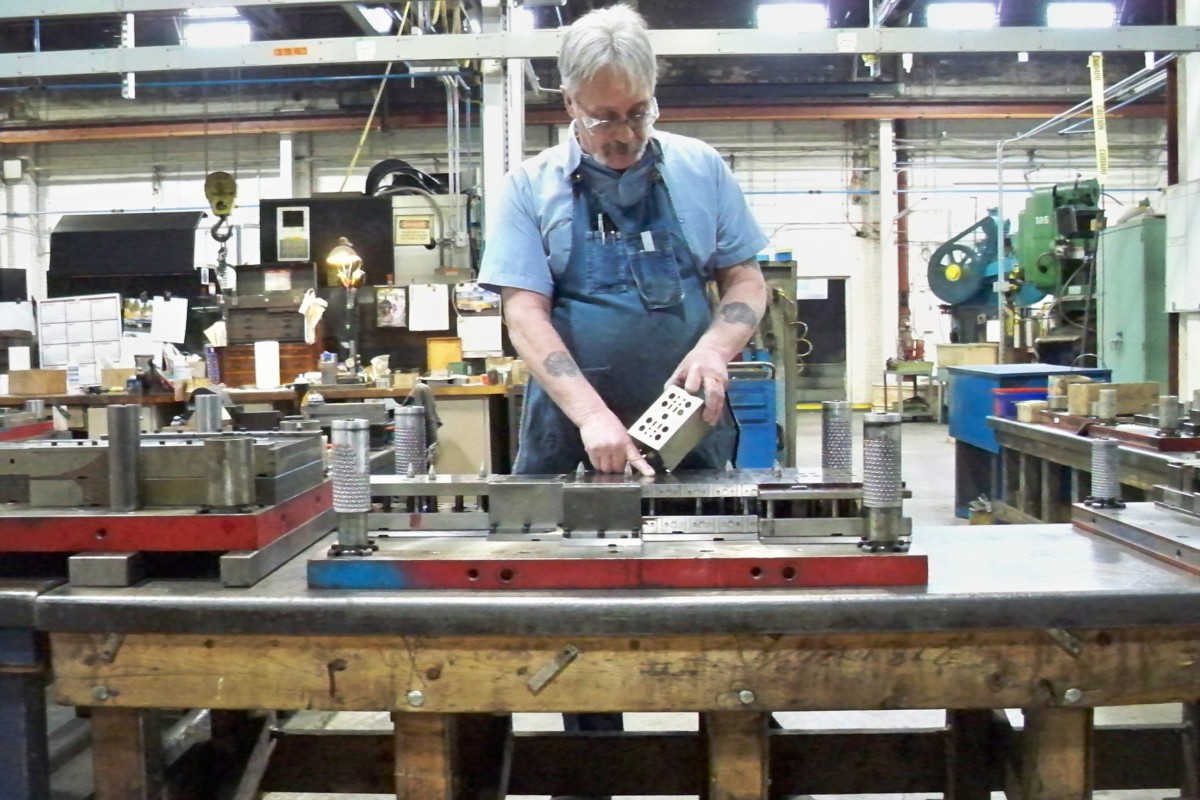

Al(left) and Rick LeBoeuf; Rick demonstrates the operation of a new CNC machine for Al during a visit to see how the industry had changed since his retirement.

What was it about Lutco that made you want to work there? Was the experience your family had working there, or something else?

My family and I worked at Lutco (Lundquist Tool & Mfg. Co.) for many years, I would calculate in excess of 120 years. My dad started in 1938 and worked until WW2 broke out. At that time he enlisted in the Army. During his 4-year absence, my mom was hired and worked to support the war effort. Upon my dad’s return from the war, he was reinstated at LT. At that time he met my mom and they married shortly thereafter. My mom worked there until approximately 1949, at which time our family began with my sister in 1950 and me in 1955. By then, O.V. Gustafson had purchased the company from the Lundquist Brothers.

Through the years I had grown to know a lot of employees through company-sponsored summer outings and Christmas banquets. They felt to be a part of my family. As a youngster my dad and my uncle (who had worked in the maintenance department) would take me along with them on the weekend, for they would routinely check the building, making certain it was secure and ready for the upcoming week, making sure the boilers were operating properly, and I would help my dad put new employee time cards in place for the upcoming week at the time clock. I was always intrigued by this and couldn’t wait to do it again the following week. They would explain to me some of the goings-on and the nature of the business and I began to understand what it was I was seeing.

I was hired part-time (late afternoon and evenings) while still attending public high school. My job was to clean the Toolroom department. This allowed me to observe the toolmakers and how they brought steel to life. This was something that I wanted to pursue. I completed a 2yr post-graduate program at Worcester Vocational Tech and my journey in the toolmaking field had begun.

Rick LeBoeuf(right) in the Lutco tool room with a toolmaker working under his supervision.

How has your time at Lutco allowed you to advance your skills? How did you impart your knowledge and experience to the next generation of employees?

I was given the opportunity to apprentice with the finest toolmakers and tradespeople in the industry and region at LT that allowed me to nurture and develop my own skills. I was also given the opportunity to lead the toolroom staff and this allowed me to continue to grow as a manager and tradesperson and to share our knowledge collectively. Hopefully, I’ve left this behind.

Family brought you into Lutco, but what made you stay?

Lutco has always been a company that has been stable throughout the years. They’ve always continued to strategically grow in many directions without compromising their integrity. The ownership has always offered steady employment and opportunity for growth if so desired.

What advice would you give to the next generation of employees?

Allow yourself never to sit back and let the world go by. Continue to strive to be better at what you do. Continue to be more effective and more efficient. This will only make what you do flow easier. Remember that you are important not only to the company but also to yourself. We all do what we do because we have a desire to succeed and that success in return is rewarded by the company.

Lutco had a profound impression on Rick’s life even before he was born; his parents met at Lutco so it was only natural Rick was drawn to a job at the company that had anchored his family’s prosperity for decades. Lutco’s commitment to employees goes beyond the traditional relationship, resulting in stories like Rick’s.

Are you interested in the stability of a manufacturing career with exceptional potential for growth and advancement? See the latest job openings at Lutco and join a team of dedicated, hardworking professionals that are truly invested in your success.