Let’s talk about one of the best ways to mass-produce metal parts and keep quality high: progressive metal stamping. At Lutco, we’ve been using this method for years to create everything from bearing parts to heavy-duty industrial stampings. And if you’re looking for a manufacturing process that balances speed, consistency, and cost-effectiveness, this might just be your best bet.

Here’s why progressive stamping stands out—and how it can work for your next project.

What Makes Progressive Stamping Different?

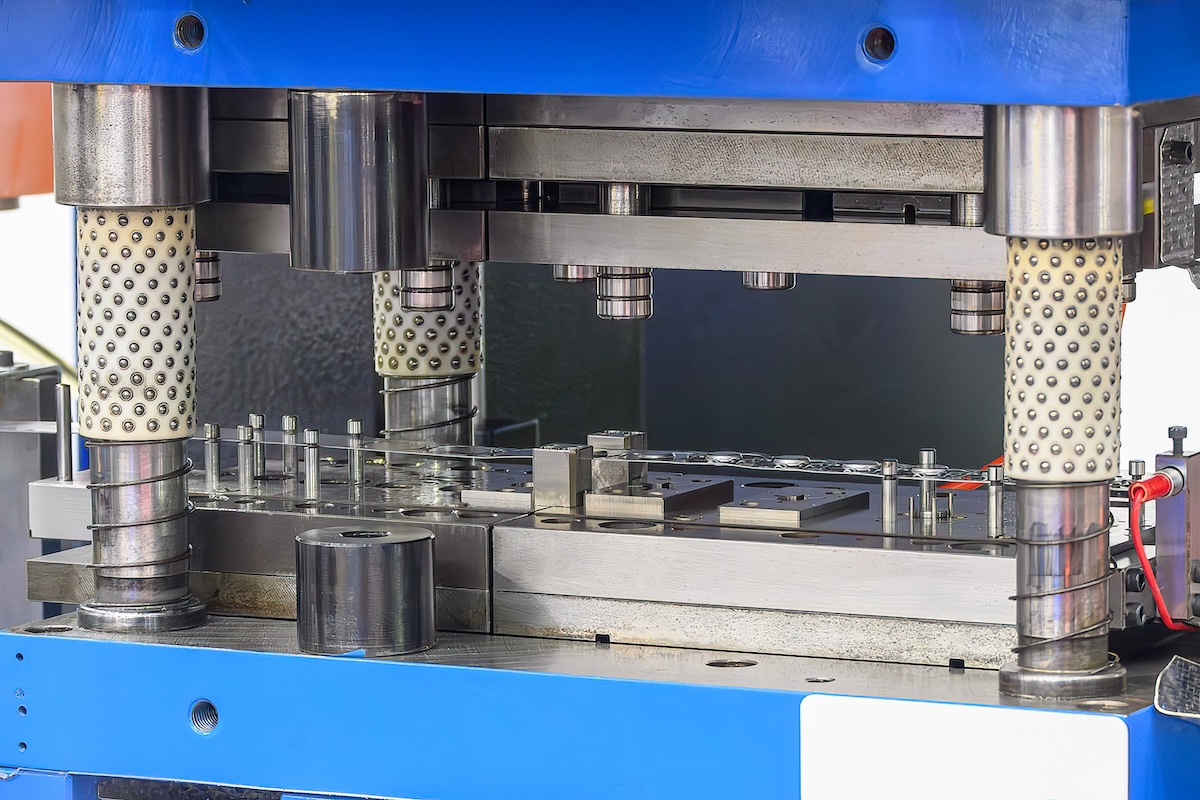

Imagine a conveyor belt of precision. Instead of making a part in multiple steps across different machines, progressive stamping feeds a metal strip through a series of stations in one continuous motion. Each station performs a different operation—punching, bending, forming, in-die tapping, piercing and cutting—until a finished part pops out at the end.

It’s like a well-choreographed assembly line, but for metal. And the benefits? They’re hard to ignore.

Why Businesses Choose Progressive Stamping

1. Speed Without Sacrifice

When you need thousands of identical parts fast, progressive stamping is the route. Production speeds are hard to beat because every stroke of the press completes another part. Automotive suppliers, aerospace manufacturers, and industrial equipment builders rely on this method when deadlines are close and volumes are high.

2. Consistency You Can Count On

Human error? Not here. Once the tooling is properly designed and set up, every part comes out nearly the same. That’s important for industries where even small variations can cause big problems (think about bearings, electrical contacts, or machinery components.)

3. Less Handling=Fewer Headaches

Traditional methods might have moving parts between machines for different operations. Progressive stamping eliminates that hassle by doing everything in one go. Less handling means fewer delays, lower labor costs, and fewer chances for mistakes.

4. Complex Shapes? No Problem

Need a part with multiple bends, intricate cutouts, formed bodies or tighter tolerances*? Progressive stamping handles it all. The multi-stage process allows for sophisticated designs that would be costly or impractical with other methods.

5. Cost-Effective at High Volumes

The first tooling investment pays off quickly when you’re producing large quantities. Once the dies are made, the per-part cost drops. This one of the most economical choices for mass production.

Where Progressive Stamping Shines

At Lutco, we’ve used progressive stamping for:

- Bearing components – Flanges, races, and retainers that need to fit perfectly every time.

- Industrial hardware and machine components– Brackets, pulleys, sprockets, and flanges that must withstand heavy use.

Is Progressive Stamping Right for You?

It depends on your needs. If you’re looking for:

- High-volume production (thousands to millions of parts)

- Tighter tolerances* and repeatability

- Complex geometries in one process

- Lower per-part costs over time

…then yes, it’s worth a closer look.

For smaller runs or simpler shapes, other methods might be more economical. But when scale and precision matter, progressive stamping is hard to top.

* Compared to casting

Let Lutco Handle Your Next Stamping Project

With 75+ years in metal manufacturing, we know how to get the most out of progressive stamping. Our in-house tool design and high-speed production mean you get parts that fit, function, and perform—without the guesswork.

Ready to see what progressive stamping can do for you?

Contact Lutco today for a consultation.